In the field of electric vehicles and industrial electrical equipment, the application of high-voltage lithium-ion batteries is gaining attention, especially in electric vehicles and industrial electric trucks. However, in the material handling industry, especially in the operation of equipment such as forklifts, whether to adopt high-voltage batteries up to 800V is not a simple question of "the more the better", but requires a comprehensive consideration of multiple factors.

Advantages and limitations of high-voltage batteries

High-voltage batteries (such as 800V batteries) are mainly used in electric vehicles to increase driving range and support rapid acceleration. However, in the material handling industry, these factors are not fully applicable. Forklifts usually follow a predetermined charging protocol and are opportunity charged at the work site, so driving range is not the primary consideration. In addition, forklifts do not need to travel at high speeds or accelerate rapidly like electric vehicles.

From a technical perspective, high-voltage batteries have higher specific power and smaller cable cross-sectional area requirements, which helps improve efficiency and reduce costs. However, this also brings safety risks, and additional safety measures and procedures are required to ensure personnel safety. In addition, the insulation layer of high-voltage batteries needs to be thicker, which may increase overall cost and complexity.

80V Batteries as a Choice for the Material Handling Industry

For off-highway industrial electric vehicles such as forklifts, tugs, and transporters, 80V may be the right high-voltage solution for most warehouse handling operations. This is because 80V batteries are able to provide enough power to meet the operational needs of the forklift without adding unnecessary mileage or weight. In addition, 80V batteries also excel in terms of cost, safety, and sustainability.

Advantages of DLNRG Lithium-ion Batteries

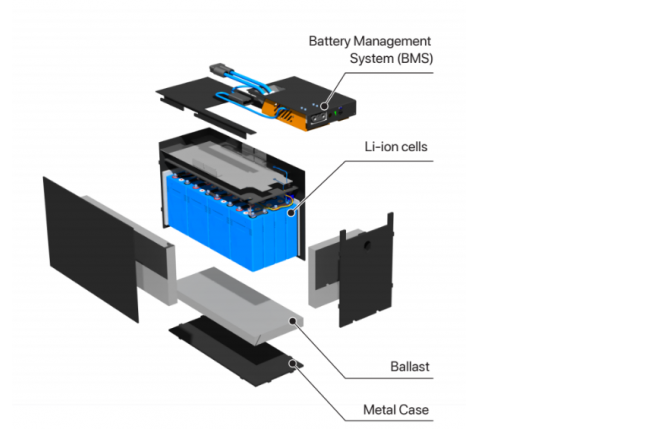

The 80V series of lithium batteries offered by DLRG offer significant advantages in the material handling industry. These batteries can be used in the most demanding applications such as heavy-duty industries and narrow-aisle applications that require maximum fork height. They demonstrate high performance, can be powered by a single battery, have high travel and lifting speeds, and have little or no voltage drop. In addition, these batteries offer advantages such as low total cost of ownership, long service life, labor or service contract savings, reduced power usage, improved safety, and sustainability.

In the material handling industry, adopting 800V high-voltage batteries is not the best choice. Instead, 80V batteries offer the best balance of cost-effectiveness, safety, and sustainability while meeting operational needs. DLNRG's 80V series lithium batteries have proven their advantages in practical applications, bringing efficient and reliable solutions to the material handling industry. Therefore, when choosing battery voltage, companies should consider factors such as operational needs, cost-effectiveness and safety to make wise decisions.