As the global economy gradually recovers from the turmoil in 2020-2021, the material handling equipment (MHE) industry is facing unprecedented delivery delays. This phenomenon not only affects the supply of new equipment, but also poses a challenge to the traditional business model of dealers. However, against this backdrop, the emergence of lithium battery technology has brought new opportunities to the industry.

1. Industry Background and Challenges

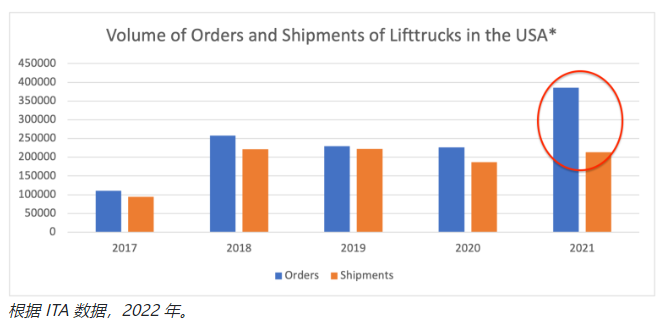

In recent years, the volume of new orders for MHE has increased significantly, but shipments have not kept up with this trend. According to the Industrial Truck Association, although new orders for MHE increased significantly in 2021, shipments increased only slightly. This has led to many dealers being out of stock and delivery times reaching record highs. In particular, in 2022, the backlog of MHE orders reached unprecedented levels, and delivery times extended from the normal 20-30 weeks to 20 months, and even up to 30 months in some cases.

2. Demand Growth and Supply Chain Disruption

The growth in MHE demand is mainly due to two reasons: first, with the healthy growth of the economy, companies process more products in factories and ship them to consumers through distributors; second, structural changes in the supply chain and distribution, such as the growth of online sales and delivery, which has prompted warehouses to gain more space. However, equipment manufacturers were not prepared for such a surge in demand under the impact of rising material and component prices. Suppliers began to prepare for unexpected situations and invested more inventory in the early stage to ensure that long-term operations are not affected by various logistics and supply chain disruptions.

3. Opportunities and Challenges for Second-Tier OEM Manufacturers

While market leaders lack inventory, second-tier companies and Asian forklift brands still have opportunities to expand their influence in the US market. However, they also face problems such as shortages of materials and parts and supply chain disruptions. More importantly, these companies need to convince the industry that they can provide high-quality services across the United States. Customers are deterred by the difficulty of purchasing maintenance, and replacements may take years to arrive.

4. Lithium Battery Solutions

Faced with this challenge, lithium batteries provide a new solution for MHE dealers. Here are the solutions that MHE dealers can offer their customers by adopting lithium batteries in 2022-2023:

Retrofit: At the end of the lease period or when the performance of the equipment has significantly deteriorated, the lead-acid battery can be replaced with a lithium battery to maintain operations. This move will improve performance and prepare for the arrival of new equipment.

Leasing: The leasing model can alleviate the dilemma of lack of new forklifts to replace old equipment. Advanced lithium batteries have longer service life and higher performance, providing dealers with the opportunity to develop attractive and profitable pricing models.

V. Conclusion

The emergence of lithium battery technology has brought new opportunities to the MHE industry. By adopting lithium batteries, MHE dealers can provide customers with more practical solutions while improving their own market competitiveness. Practical knowledge and experience with new lithium technologies will continue to drive sales growth in the coming years. Although the supply chain may not be stable in the short term, the application of lithium batteries will provide strong support for enterprises to survive this challenging period.