With the increasing awareness of environmental protection and the improvement of energy efficiency, electric forklifts are becoming increasingly prominent in the material handling industry. Since 2018, more than half of forklifts sold in the United States have been electric, and this trend is still accelerating. Electric forklifts not only reduce operating costs and total cost of ownership, but also provide a safer, cleaner and quieter environment in the workplace. Among them, the introduction of lithium battery technology makes electric forklifts suitable for more heavy-duty applications.

Transition from LPG to lithium batteries

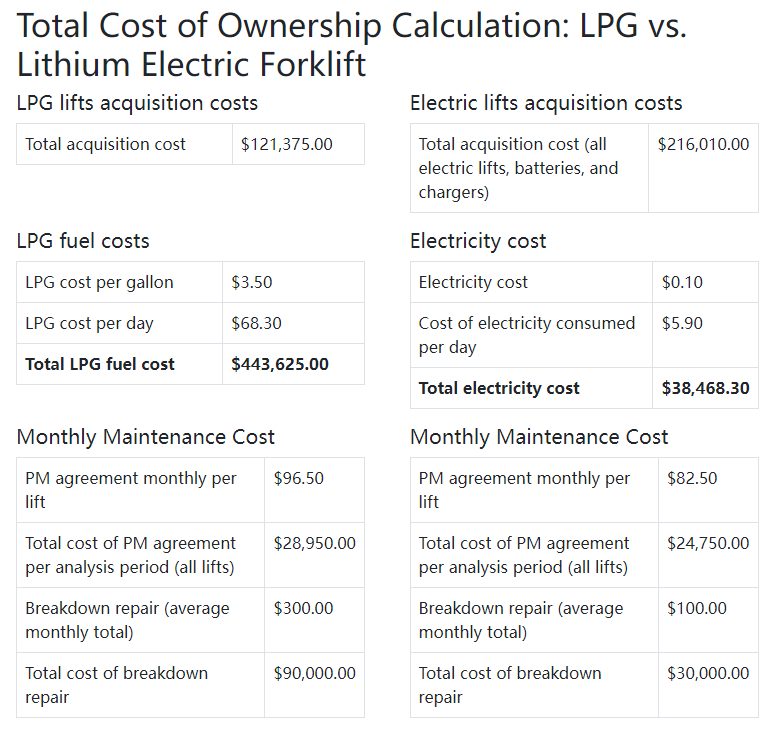

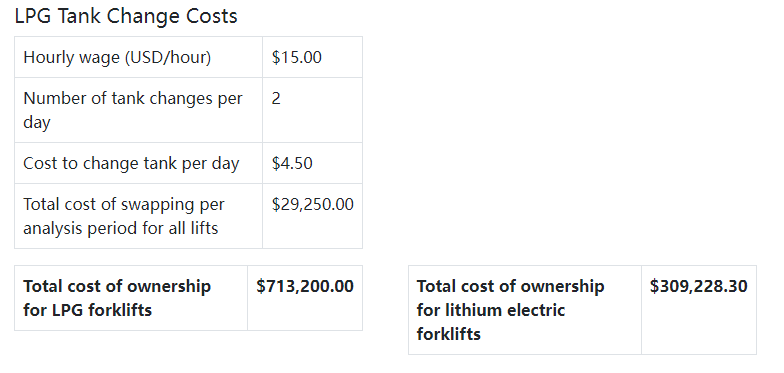

Liquefied petroleum gas (LPG) forklifts have occupied a place in the market with their relatively low noise and air pollution levels and cost-effectiveness. However, LPG forklifts still have higher operating and maintenance costs compared to electric forklifts. In addition, as society's awareness of environmental protection increases, the environmental benefits of electric forklifts are becoming more and more significant. Therefore, the transformation from LPG forklifts to electric forklifts has become a general trend.

As the core power source of electric forklifts, lithium batteries have the advantages of high energy density, fast charging speed and long cycle life. Compared with lead-acid batteries, lithium-ion battery packs can store more energy in a battery compartment of the same size, thus meeting the needs of more applications with high energy throughput. In addition, lithium batteries can be quickly charged during breaks and lunch times to maintain efficient operation for multiple shifts per day.

Calculation of Ah capacity

Correctly calculating the Ah capacity of the lithium battery is crucial when converting an LPG forklift to an electric forklift. This requires an apples-to-apples comparison, i.e. ensuring that the engines are similar in terms of energy and power output.

A conventional internal combustion engine (ICE) powered by LPG provides about 3.25kWh of energy per gallon. Assuming the LPG forklift's fuel tank capacity is 8 gallons, a full tank can provide 26kWh of energy. A modern LPG forklift consumes about 2.5 tanks of fuel per day (spread over 3 shifts), so the energy required per day is 78kWh.

To match this energy output, a lithium battery with appropriate voltage and Ah capacity can be selected. For example, an 80V, 1050Ah lithium battery can provide 84kWh of energy (80V x 1050Ah = 84kWh), which is slightly more than the energy required by an LPG forklift on a daily basis. This battery capacity ensures that the electric forklift can operate efficiently during three shifts a day, while retaining extra power to cope with unexpected situations or missed charging events.

Why do LPG forklifts still exist?

Despite the obvious advantages of electric forklifts, some companies still insist on using LPG forklifts. This is mainly attributed to inertia, long-standing business relationships with local material handling equipment (MHE) dealers and lack of familiarity with new lithium technologies. In addition, the outdoor working environments of some specific industries (such as the wood, paper and recycling industries) may also be more suitable for LPG forklifts.

However, these issues will be resolved in the near future. As society reaches a consensus on the urgency of transitioning away from fossil fuels and the economic benefits of electric forklifts become increasingly apparent, more and more companies will turn to electric forklifts. In fact, some regions have already formulated relevant policies to promote this transformation. For example, California will not allow the sale of new forklifts that are not zero-emission starting in 2026.

Wide application of lithium batteries

Lithium batteries are not only widely used in electric forklifts, but also show great potential in other heavy machinery. Successful commercial projects include electric cranes and excavators for the construction industry and locomotive engines for trains. Experiments are underway in the maritime transport sector, and aviation will soon follow. It is foreseeable that the future of electric devices will be dominated by lithium batteries.

To sum up, the transformation from LPG forklifts to electric forklifts is an inevitable trend. Correctly calculating the Ah capacity of lithium batteries is key to ensuring efficient operation of electric forklifts. With the continuous advancement of technology and the promotion of policies, electric forklifts will play an increasingly important role in the material handling industry.