Recently, the California Air Resources Board (CARB) updated the proposed zero-emission forklift regulation to further promote the green transformation of the material handling industry. The first draft of the regulation was released in February this year, and after a series of revisions, it clarified the phase-out plan for internal combustion engine (ICE) forklifts and the promotion requirements for zero-emission forklifts. The following is a detailed analysis of these revisions and their potential impacts.

Key points of regulatory changes

Turnover cap and phase-out period:

Class IV forklifts: During the first four-year phase-out period, the company must hand over at least 25% of the forklifts. The phase-out period is shortened from 13 years to 10 years.

Class V forklifts: During the first six years of the phase-out period, the company must hand over at least 15% of the forklifts each year. For small fleets with 25 or fewer Class V forklifts, the phase-out period is postponed to 2029.

Reduced reporting requirements: Compared with the first draft, the regulation reduces the reporting requirements for fleets to reduce the administrative burden on companies.

Leasing agencies included in the phase-out plan: Leasing agencies also need to follow the same phase-out measures as fleet operators, but fleets renting forklifts are no longer subject to the 30-day usage limit per year.

Exemptions and subsidies: The regulations include a number of exemptions and subsidy policies, such as low-use exemptions and leasing subsidies, to ease the transition pressure on companies.

Potential impact analysis

Impact on fleet operations:

Fleets need to plan ahead to ensure that the transition to zero-emission forklifts is completed before the regulations take effect.

For fleets with older models, the initial replacement cost may be higher, but in the long run they will benefit from lower operating costs and a better environmental image.

Impact on the material handling equipment industry:

The regulations will promote the rapid development and popularization of zero-emission forklift technology.

Lithium battery manufacturers will face greater market demand and need to increase production to meet the demand for zero-emission forklifts.

Special considerations for small fleets:

Small fleets benefit from the postponement of the phase-out deadline and have more time for planning and funding.

However, small fleets may face greater challenges in technology transformation and need to seek professional support and cooperation.

Chain reaction outside the industry:

The implementation of the regulations may trigger similar policy discussions and formulation across the country.

The supply chain of material handling equipment may be adjusted to adapt to new market demands.

Case Study

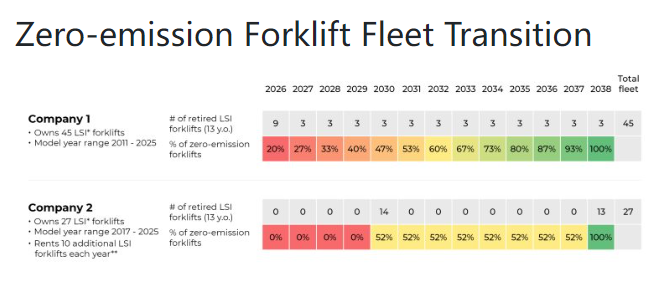

Company 1: A fleet of 45 LSI forklifts with a wide range of model years. Starting in 2026, a certain number of old model forklifts will need to be eliminated each year and replaced with zero-emission forklifts. Despite the initial replacement pressure, the fleet can retain some low-use forklifts to reduce the burden.

Company 2: A fleet of 27 LSI forklifts with uneven model year distribution. Due to the concentration of models, the fleet does not need to eliminate a large number of forklifts for a period of time. However, over time, there will be a large-scale replacement demand. The fleet needs to develop a smart planning strategy to meet future challenges.

Conclusion and Outlook

The implementation of California's zero-emission forklift regulations will have a profound impact on the material handling industry. Despite many challenges, the promotion of regulations will accelerate the green transformation of the industry and promote the popularization and development of zero-emission forklift technology. For the fleet, advance planning and proactive response will be key. At the same time, all parties such as the government, industry associations and lithium battery manufacturers also need to strengthen cooperation to jointly promote the smooth implementation of regulations and the sustainable development of the industry.

In the future, with the continuous advancement of zero-emission forklift technology and the reduction of costs, as well as the continued promotion of government policies, zero-emission forklifts will become the mainstream choice in the material handling industry. Fleets need to keep up with the times and actively embrace change to achieve more environmentally friendly, efficient and sustainable operations.